DİGİTAL AUTOMATION SYSTEM

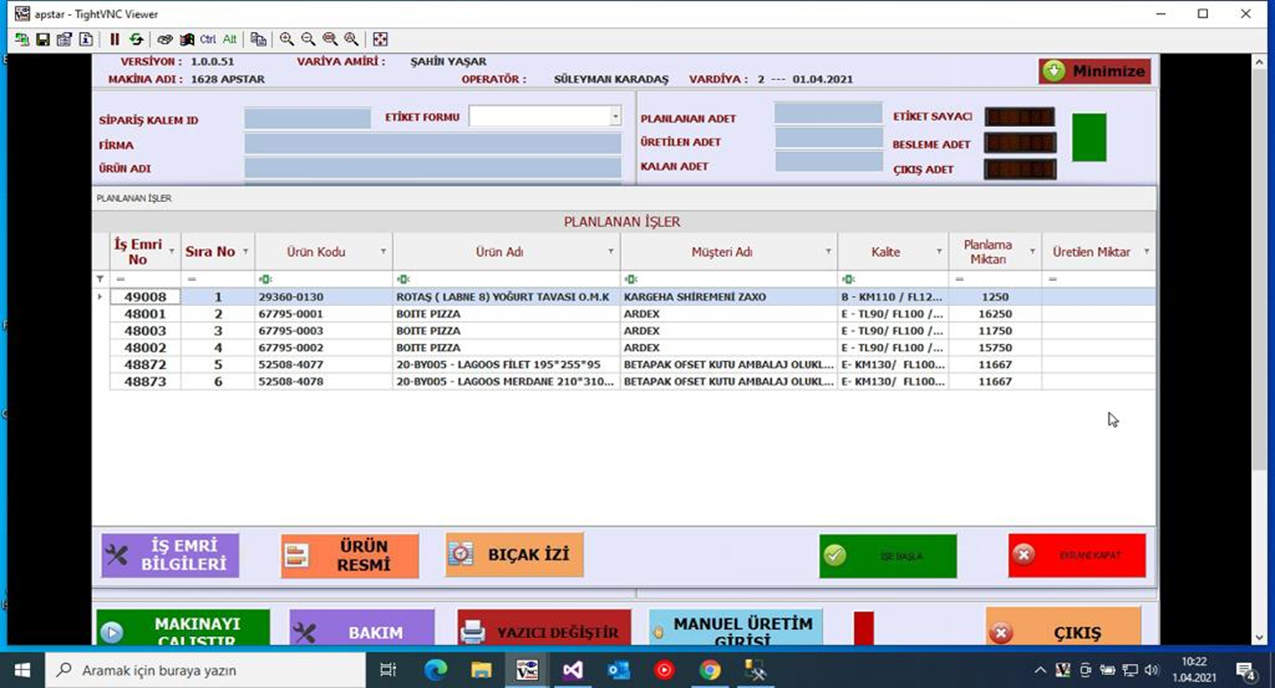

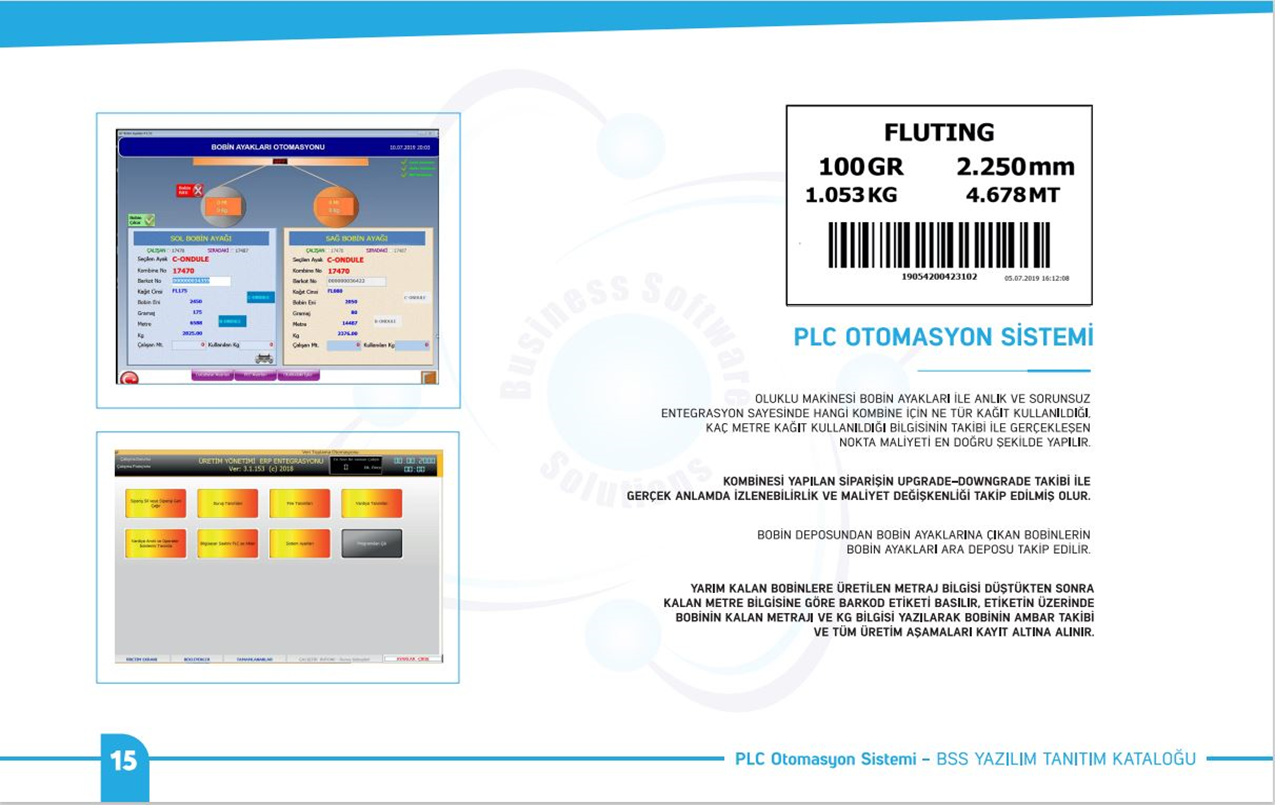

With the PLC and sensors to be installed to the machines through PLC automation, machine plans to be create by ERP will be directly transferred to the interface screens of operators with the given plan order, and thus situations including the most frequent mistakes will be eliminated such as wrong stereotype or mold connected toy he machine by the operators entering the setting times wrong, not correctly tracking the stopping times, not correctly tracking thewastes, not correctly tracking the semi-finished and finished product inventories entering to and exiting from the machine , wrong productions arising from omitting the work details of planned Works as well as not tracking the machine shift and personnel performances related to this structure.

- SENDING THE PRODUCTION PLAN TO THE MACHINE TOGETHER WITH THE WORK ORDER

- EFFECTIVE TRACKING OF PRODUCTION TARGET TIMES

- DISPLAYING THE PRODUCT PRINT FORM IMAGES ON THE OPERATOR SCREEN

- ÜRÜNLERE KALIP VE BIÇAK ÇİZİMLERİNİN GÖRSELLERİNİN OPERATÖR EKRANINDA GÖRÜLMESİ

- ÜRETİLECEK OLAN ÜRÜN VE SİPARİŞ BİLGİLERİNİN ANLIK ŞEKİLDE OPERATÖR EKRANINDA GÖRÜLEBİLMESİ

- ÜRETİM VE SATIN ALMA SÜRECİNDEKİ AKSİYONLARIN ANLIK VE DOĞRU BİR ŞEKİLDE OPERATÖR TARAFINDAN TAKİP EDİLEBİLMESİ

- MAKİNE ÜRETİMİNDEKİ YARI MAMÜL VE MAMÜL STOK TAKİPLERİNİN ANLIK BİR ŞEKİLDE YAPILMASI

- REMOTE INTERVENTION TO THE MACHINES BY MOBILE PHONES WITH THE NETWORK

- STRUCTURE TO BE ESTABLISHED BETWEEN THE MACHINES AND THE WEB-INTERNET SYSTEM TO BE ESTABLISHED ON PLC

- EFFECTIVE PROCESS AND PRODUCTION TRACKING BETWEEN THE MACHINES

- COMPARING THE TARGET PRODUCTION AND REALIZED PRODUCTION TIMES TO BE TRANSMITTED TI THE MACHINES TOGETHER WITH THE PLANS

- AUTOMATIC AND ERROR-FREE RECORDING OF MACHINE SETTING TIMES THROUGH THE ALGORITHMS DEVELOPPED SPECIALLY FOR THE SECTOR AND PRODUCTION PROCESS

- GETTING PRODUCTION QUANTITIES INSTANTLY FROM PLC AND SENDING THEM TO THE SYSTEM

- TRANSFERRING THE PRODUCTION TIMES INSTANTLY AND ERROR-FREE TO ERP

- INSTANTLY TRACKING ALL THE SHOPPINGS OF THE MACHINE AND NOT BEING ABL TO RUN THE MACHINE WITHOUT ENTERING THE REASON OF STOPPING

- EVEN IF THE MACHINE RUNS DURING THE SHIFT CHANGES, GETTING THE PRODUCTION QUANTITIES AND PRODUCTION TIMES AUTOMATICALLY AT THE END OF SHIFT WITHOUT STOPPING THE MACHINES AND RECORDING THEM IN THE ERP APPLICATION